I have been bitten by the Marine bug and cannot fit two display tanks in the houseAfter years of Discus I have to say goodbye however thought I would share my latest build.

Introduction:

I have been keeping FW fish for 20 years and setup a small Reef Nano in 2010. With the success of the Nano I have decided to decommission my Jewel Vision 450 discus tank and replace this with a 4 foot marine. My background is process control & automation and it will come as no surprise that the majority of my previous tanks have had various degrees of Instrumentation / automation associated with them. This tank will be no different however the design goal is reliability of equipment and ease of repair if something was to fail.

System Objectives:

I am looking for a modern design for both the stand, tank and aquascape with the goal of trying to either reduce maintenance or build something that enables tank maintenance to be done faster. Access to equipment and layout are important aspect in lowering the maintenance workload and I am trying to think hard to incorporate this into the design.

Tank: 1300x520x480high rimless starfire glass. The tank height troubled me the most as I considered the lighting (T5’s), ease of maintenance and the overall ratio of length ver height. Thought process was I wanted to create more of a “wide screen ” cinema look to the tank.

Stand: Design will be modeled off my previous Nano tank, MDF veneer construction. The cabinet itself will be smaller than the tank so that the tank looks like its floating above the cabinet. The downside is the room available for equipment under the tank is smaller thus the sump had to be compromised in its size and function.

Aquascape: Minimalistic with two islands of rock/coral and lots of open sand. The open area concept maybe a challenge in a small 4’ tank.

System Type: Mixed Reef

Display System:

Strike up Date: Design / procurement started May 2011, tank completed (projection is end of July 2011)

Display Tank: 1300x520x480h rimless starfire (front only) all sides 12mm glass construction.

Display Lighting: ATI Power Module 6x54W T5. 6 tube unit was selected over the 8 or 10 on the basis of running costs, physical size, coral preference and presumed light distribution. I understand the larger tube units do not necessarily give a higher par output however simply spread the light over a larger area. As I plan on having my corals on two islands in the centre line of the tank I should get enough light directly under the fixture to support a variety of corals. The light will be suspended over the tank on a height adjustable frame. This frame includes a 12Vdc linear actuator which will enable the light to be elevated from 50-350mm above the water line via a control panel.

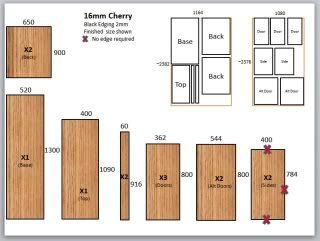

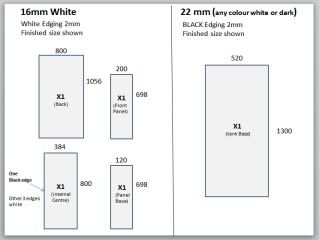

Stand: DIY custom built, MDF veneer, edges sealed prior to assembly and will have a silicon bead run around any edge where water may collect on a spill. The internal cabinet sump area will have a secondary white laminate covering and again fully sealed. There is no plan for a steel or pine support frame and will rely on the “slab” style MDF construction to hold the weight, its only a 4’ tank. The MDF is water resistant, (not water proof). The veneer will be professionally cut and edged with a 2mm black edge strip so with the idea of creating a flat pack cabinet which will only need assembling.

Hood: Open top design

Sump: The sump size is compromised by the small cabinet and style of the stand. For the first phase the sump will simply be a two compartment 550mm long AGA with a bubble trap.

Support systems:

System Water: Artificial salt water

Display Water circulation:

I will use the Tunze rear mount overflow in the DT with tunze connection tubing down into the sump. The sump includes the Tunze sump assembly which has an integrated sock.

The DT circulation will be via two Tunze nanostream controlled via the Tunze 7096 USB controller

Return Pump:Tunze silence

Skimmer: Tunze 9011, selected due to small sump

Evaporation Top Up:

Will use a stainless steel dual ganged float switch within the sump connected through a hardwired relay to control a Tunze ATO pump. This will be monitored by a custom control panel however operate independently.

Cooling:

I plan to use simple fans (4) blowing across the water surface and see how this goes to reduce temperatures when required. The fans are mounted on the rear bar of the light stand and normally positioned just lower than the DT back wall. When the light is moved up 100mm it will expose the fans and they will turn on.

Chemical Support:

Calcium/ Alk Addition: Two part dosing via Peristaltic pumps connected to Control Panel

Basis of Pump Design Flow:

Volume DT = <300 litres (80G)

Volume Sump = ~30 ~50 litres based upon level of 18cm - 30cm (45 cm MAX)

DT drain to sump when return pump is off, estimated at water level drop of 20mm in DT = ~13 litres

Sump return flow = 3~5 x DT Volume = 900 ~ 1,500l/hr (240-400 gph)

DT turnover flow 25~30 x DT volume = 7,500 ~ 9,000 l/hr (2,000-2400 gph)

Images:

Cabinet Design -Currently under development

ATI Powermodule, fan cooled 6x54W T5 -Delivered

Light rail completed -Actuator not attached. Constructed out of T section aluminum extrusion, VERY strong and easy to assemble

Actuator for Light 12VDC 50kg lift, 300mm stroke with internal limit switches

400mm Linear potentiometer -used for monitoring light position above DT

the idea is you will be able to input the distance you want the light to be above the DT and the controller will position it at that hieght.

Tunze Equipment -Delivered

Wall Overflow <1,500l/hr, -Outlet Filter - Outlet Host

DOC Skimmer 9011 ~1,000 l tank, - Silence Return Pump 24VDC electronic adjustable flow 1,000-300l/hr

Reactor Pump 240VAC mechanical adjusted flow 150-800 l/hr

Turbelle DT Flow all low voltage variable flow - 24VDC

Tunze 7096 Controller, 6055 nanostream 5,500l/hr -Will wait to Aug until the release of the 6095 nanostream 10,000 l/hr

Control Panel, low voltage switching only 12 and 24VDC -Completed

12 digital outputs 6 Analog Inputs, 2 pulse inputs, 4 PWM outputs, 8 Digital inputs, 2 temperature inputs via RTD

New 1wire Controller used in control panel -BETA Version, working with developer in early product phase

Sump Return Flowmeter 0-4000 l/hr

Electrodeless Conductivity Transmitter used for online SG and temperature measurements range 0-100ms

Results 1 to 2 of 2

Thread: New Marine tank,

Threaded View

-

Thu Jun 09, 2011, 01:48 PM #1Medium Discus

- Join Date

- Jul 2004

- Location

- Eastern Suburbs... VIC

- Posts

- 671

New Marine tank,

My online Aquarium www.rjconway.homeip.net

Reply With Quote

Reply With Quote